Ama-Polycrystalline Diamond Compact PDC Cutters Okugaya Amafutha Negesi

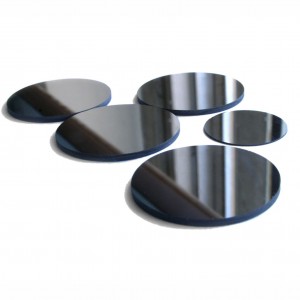

Ama-Polycrystalline Diamond Compact PDC Cutters Okugaya Amafutha Negesi

1.Iyini impahla ye-PDC?

I-PDC- I-Polycrystalline diamond compact yenziwe nge-polycrystalline diamond layer kanye ne-tungsten carbide substrate, ungqimba lwedayimane lwe-polycrystalline lunobulukhuni obuphakeme kakhulu nokumelana nemihuzuko kanti i-tungsten carbide substrate ingathuthukisa kakhulu ukusebenziseka kalula nekhono lokushisela layo yonke inhlanganisela, umquba wedayimane we-polycrystalline kusetshenziswe uphethiloli wokumba umthombo kawoyela, ukuhlola i-geology, izimayini zamalahle kanye nemboni yemishini.

I-Polycrystalline diamond compost (PDC) yokusika ifaka yokumba elungele indawo ethambile iye kweqinile ye-geological ngokwesidingo samakhasimende singanikeza i-polycrystalline diamond compact enezinhlaka zozipho kanye nezinhlobo ze-chamfer noma ngabe zigaya noma zingapholishwa, singahlinzeka ngabasiki be-PDC ngesimo esikhethekile i-oda lamakhasimende.

I-GAS series PDC cutter ye-petroleum ne-gas drills inokumelana nomthelela ophezulu kanye nesilinganiso sokuguga, impilo ende yesevisi kanye nokusebenza kahle okuphezulu kokubhola ngaphansi kwendawo ezungezile.ilungele ukwakheka kwamatshe athambile naphakathi.

2. Ukucaciswa kwe-GAS series PDC cutter

| Ikhodi # | Ububanzi (mm) | Ubude (mm) | Idayimane Ithebula |

I-Charmfer | I-Wear Ratio | Umthelela Ukumelana |

| I-GAS1308 | 13.44±0.05 | 8.0±0.1 | 1.8~2.0 | 0.41±0.05 | >40 | >1600 |

| I-GAS1313 | 13.33±0.05 | 13.00±0.1 | 1.8~2.0 | 0.41±0.05 | >40 | >1600 |

| I-GAS1608 | 16.0±0.05 | 8.0±0.1 | 1.8~2.0 | 0.41±0.05 | >40 | >1800 |

| I-GAS1613 | 16.0±0.05 | 13.00±0.1 | 1.8~2.0 | 0.41±0.05 | >40 | >1600 |

| I-GAS1908 | 19.0±0.05 | 8.0±0.1 | 1.8~2.0 | 0.41±0.05 | >40 | >2000 |

| I-GAS1913 | 19.0±0.05 | 13.00±0.1 | 1.8~2.0 | 0.41±0.05 | >40 | >2000 |

| I-GAS1916 | 19.0±0.05 | 16.0±0.1 | 1.8~2.0 | 0.41±0.05 | >40 | >2000 |

3. Umlingiswa we-GAS PDC Cutter

1) Ngesici sokusebenza kahle okuphezulu, indawo ebushelelezi

2) Amatheknikhi athuthukile nokulawula inqubo eqinile

3) Isikhathi eside sokuphila nokusebenza okuzinzile

4) Intengo yokuncintisana kanye nekhwalithi ephezulu

4. Enye i-PDC Cutter Shape