I-FCCS07 FeCuCoSn Pre Alloyed Metal Powde Yamathuluzi Edayimane Ekhwalithi Ephakathi Nephezulu

I-FCCS07 FeCuCoSn Pre Alloyed Metal Powde Yamathuluzi Edayimane Ekhwalithi Ephakathi Nephezulu

1. Iyini I-Pre-alloyed Powder

Izimpushana ezifakwe ngaphambili ziqinile, azicindezeli kancane futhi yingakho zidinga imithwalo ephezulu yokucindezela ukuze zikhiqize ukuminyana okuphezulu.Kodwa-ke, bayakwazi ukukhiqiza izinto ezisezingeni eliphakeme ze-sintered.I-pre-alloying iphinde isetshenziswe lapho ukukhiqizwa kwezinto ezilinganayo kusuka ku-elemental powders kudinga izinga lokushisa eliphezulu kakhulu kanye nezikhathi ezinde ze-sintering.Izibonelo ezinhle kakhulu izinsimbi ezingenasici, okuqukethwe kwe-chromium ne-nickel kufanele kufakwe ngaphambili ukuze kuvunyelwe ukukhiqizwa komnotho nge-powder metallurgy.

2. Amapharamitha we-FCCS07

| Isici Esiyinhloko | Fe, Cu, Co, Sn |

| Ukuminyana kwethiyori | 7.84g/cm³ | |

| I-Sintering Temperature | 790℃ | |

| Ukugoba Amandla | 1500Mpa | |

| Ukuqina | 105-110HRB |

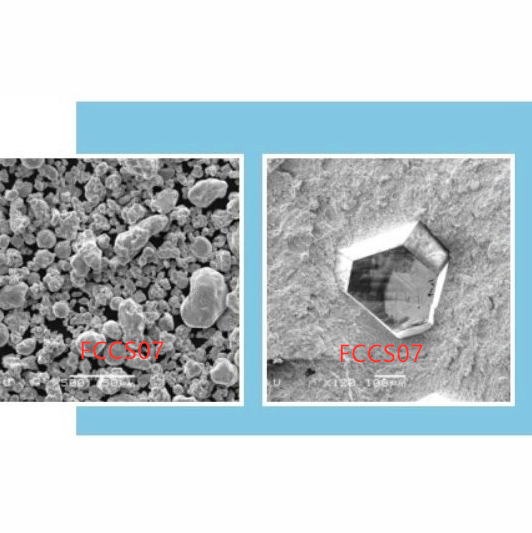

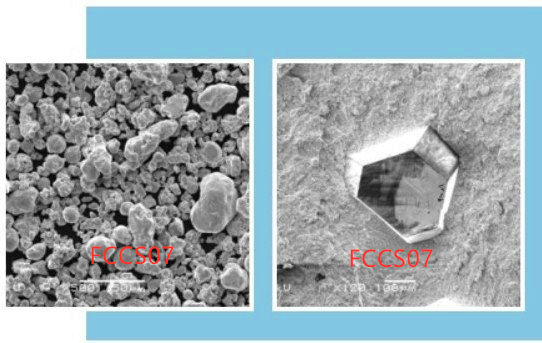

3. I-FCCS07 Inhlamvu Yempushana Efakwe Ngaphambili

- Impushana inekhono elihle lokumanzisa idayimane kanye ne-granulating enkulu yomshini kwezinye izimpushana zensimbi, ingasiza imikhiqizo ukuba izuze inani elikhulu ngesivinini kanye nempilo.

- Ifakwe kucwecwe lwedayimane legwadle eliphakathi kuya kwephezulu, icwecwe ledayimane le-ceramic, intambo yedayimane kanye nezingcezu eziyinhloko zedayimane

4. Imiyalo Yokusetshenziswa Kwe-Ceramic Cutting Blade

- I-Metal Powder

- 30-50% FCCS07

- + 25-35% Cu

- + 3-6% Sn

- +2-5% Ni

- + 7-10% CUCS

- + I-Fe yebhalansi

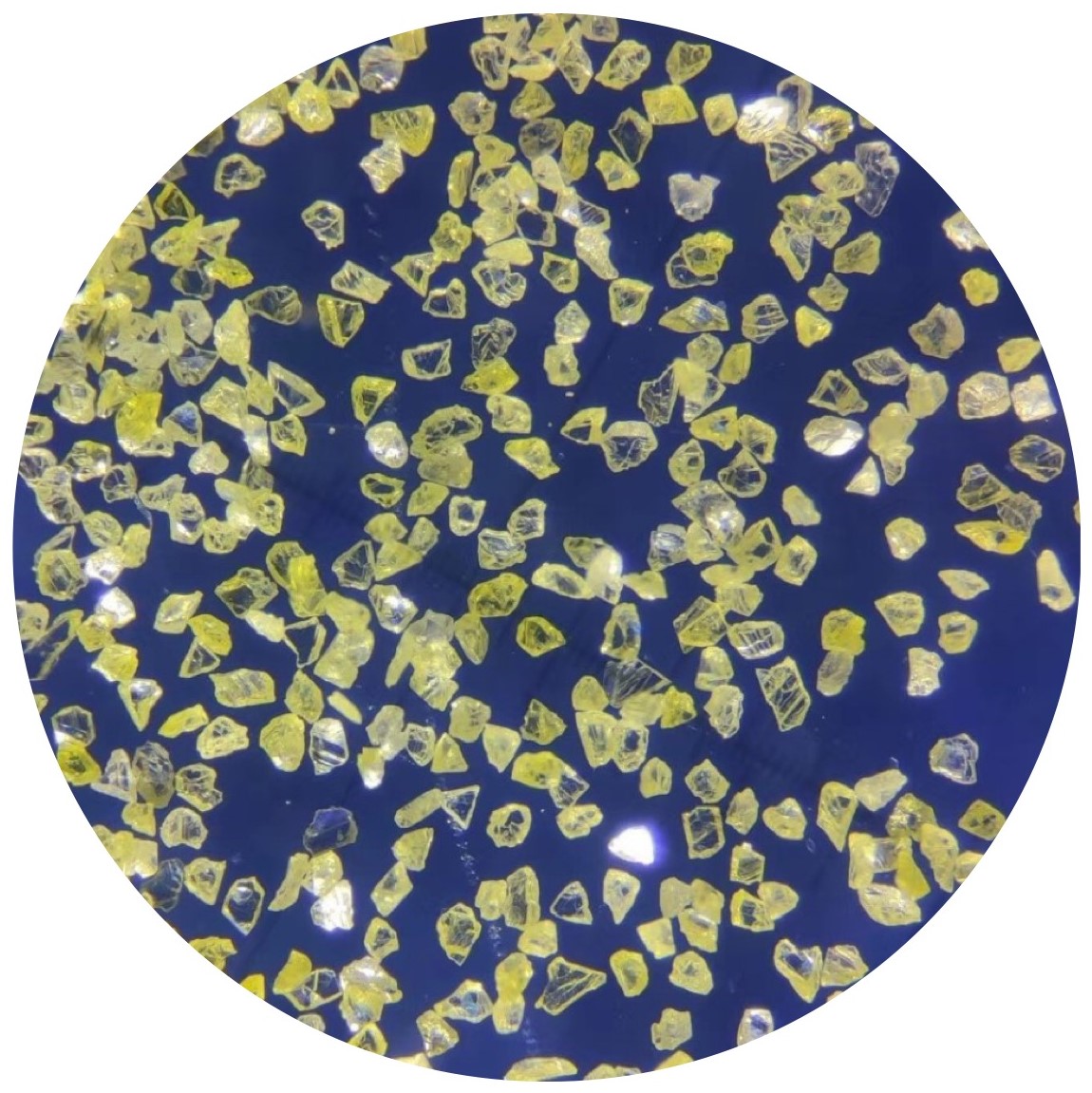

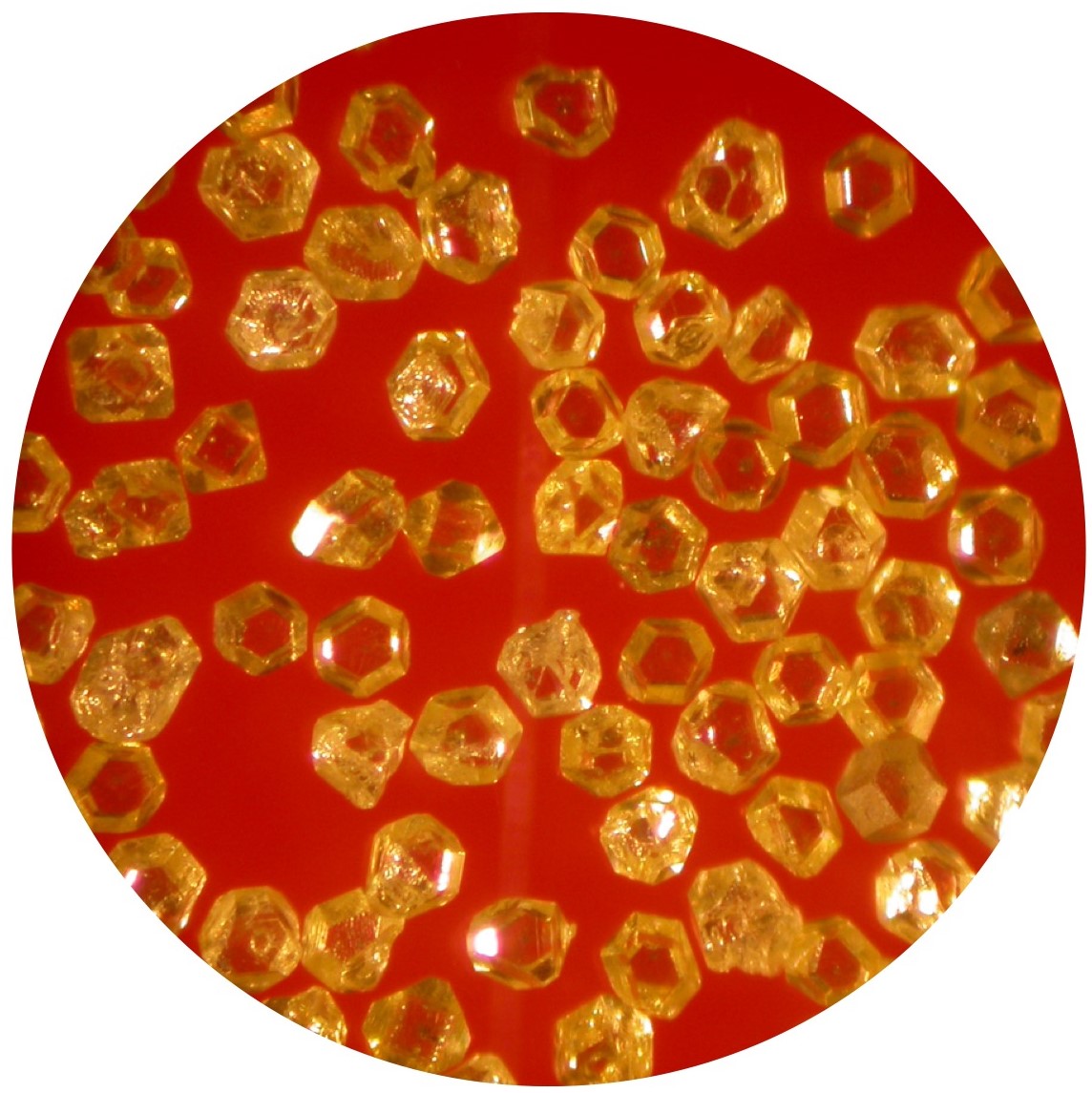

B. Idayimane le-Dry Cutting Ceramic

- 50/60 @ 30%

- 60/70 @ 40%

- 70/80 @30%

- Ukugxila Kwedayimane @ 13-15%

C. Idayimane leCeramic yokusika emanzi

- 50/60 @ 60%

- 60/70 @ 40%

- Ukugxila Kwedayimane @ 10-12%

D. I-Sintering Temperature 830-850℃